Technology - Milk Coagulation

The enzymatic coagulation of milk proceeds with three primary overlapping chemical reactions. It is the measurement of the enzymatic reaction rate that distinguished the CoAguLite technology.

Enzymatic Hydrolysis of Casein

The first chemical reaction is the enzymatic reaction of chymosin and casein which destabilizes the colloidal nature of casein micelle. The initial phase of the enzymatic reaction when the substrate concentration (casein) is in excess supply in relation to the enzyme concentration can be modeled with a first order chemical reaction.

Aggregation of casein

The second chemical reaction is the aggregation of the destabilized casein micelle into flocks which grow and consume the entire casein particulate system. It is during this phase that larger particles are formed and the reflectance of light increases. The aggregation reaction follows a second order chemical reaction.

Gel Forming Reactions

The third phase is the gel forming phase which results from a micro consolidation of protein strands that result in stronger protein strands and an increasing space within the protein matrix. This phase follows a first order chemical reaction.

Parameter Estimation (response-based and time-based)

The CoAguLite backscatter sensor yields a time-based parameter or an event, tmax. The event is the time when aggregation is at a maximum.

Effect of Milk Properties and Processing Conditions

In our research we have developed cutting time prediction models which use response-based parameters. Excellent prediction models resulted, however, in ALL cases studied the models which use time-based parameters proved to be more accurate predictors of cutting time. Additionally, and most importantly, the time-based parameter tmax when used in the simple cutting time prediction model described below has proved to be independent of the effect of pH, fat, calcium addition, enzyme concentration, and temperature but not protein (Payne, 1993). The time-based technology is thus generally applicable (with protein considerations) for predicting cutting time over a wide range of product and processing conditions normally encountered in cheese making. This is the major advantage of the CoAguLite technology.

The CoAguLite Cutting Time Prediction Technology uses a combination of time-based parameters obtained from the analysis of the reflectance profile and protein content to predict cutting time. Payne and Castillo (2007) have summarized the light backscatter technology. The CoAguLite technology is based on chemical reaction kinetics. The three chemical reactions (enzymatic hydrolysis, aggregation, and gel firming) have reaction rates which are affected differently by temperature, pH, calcium ion concentration, and enzyme concentration but over the small change encountered in cheese processing the changes are approximately proportional. Thus because they are approximately proportional a temperature increase of 2 C will increase both enzymatic reaction and gel firming reactions approximately an equal percentage. Thus, if the enzymatic reaction rate can be measured precisely then it is possible to predict the change in gel firming reaction.

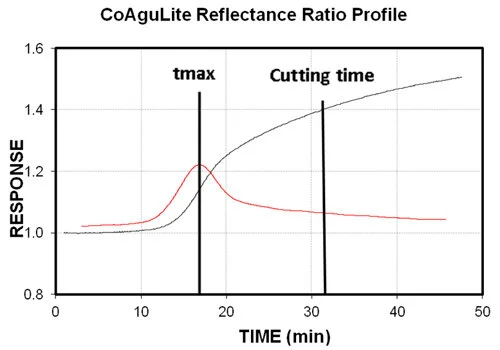

The single most important time-based parameter measured by the CoAguLite technology is time from adding enzyme to the occurrence of the maximum rate of change of reflectance, t1max1 or tmax. The determination of tmax is shown in Figure 1.

Figure 1. A typical reflectance ratio profile (black curve) with the first derivative (red curve) from the CoAguLite sensor showing the determination of the time-based parameter tmax

It has been shown by Saputra (1992) that tmax is a direct measure of the enzymatic reaction rate constant. Recently Nasrin Tabayehnejad et al (2009) showed that tmax could measure the enzymatic reaction rate so accurate that it could replace the Berridge clotting time for measurement of total milk-clotting activity of rennet. Thus, the time-based parameter tmax is an accurate measurement of the enzymatic reaction rate in coagulating milk and, by linear extrapolation; it measures the gel firming reaction rate. This is a major advantage of the CoAguLite technology.

The single most important time-based parameter measured by the CoAguLite technology is time from adding enzyme to the occurrence of the maximum rate of change of reflectance defined as tmax (referred to in some publications and programming as T1MAX1). The determination of tmax is shown in the Figure 1.

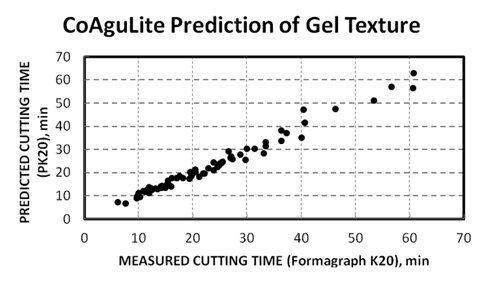

A test was conducted (Payne et al 1993) that compared the light backscatter response with gel texture as measured using a Formagraph (Foss Electric, Denmark). The cutting time was defined as the time after enzyme addition when the texture forced the oscillating pens on the Formagraph to trace a pattern spaced 20 mm apart. This time was designated K20. Over 200 coagulation tests were tested with three levels each for temperature, pH, calcium addition, fat content, protein content and enzyme concentration. The levels were selected to cover a broad range of conditions encountered in the cheese making. Figure 2 shows the correlation between K20 and predicted cutting time PK20 using a proprietary cutting time prediction equation.

Figure 2. The measured Formagraph cutting time,K20, compared to the predicted cutting time using the time-based parameter, tmax, determined using light backscatter and the cutting time prediction equation PK20 = Beta* tmax *(protein function).

The simple cutting time prediction equation developed for the CoAguLite technology is PK20 = Beta* tmax *(protein function) where K20 is the cutting time measured by the Formagraph, tmax is the optically determined parameter, Beta is a calibration constant determined by the plant cheese maker, PK20 is the predicted cutting time and (protein function) is a small adjustment made for protein content.

Figure 2 shows that the measured cutting time (K20) and the predicted cutting time for the above cutting time prediction equation fall very close to a straight line. The standard error for the data with a cutting time (K20) below 35 min was 72 seconds. However, the 72 seconds was for test conditions where the product variability was tested. For normal cheese making operations, the processing conditions are nearly constant and the variability is significantly less. The great beauty of the CoAguLite cutting time prediction technology is that only one variable, Beta, is required for calibration. This is THE only calibration required for the CoAguLite technology. The cheese maker calibrates the technology by selecting beta. The cheese maker does this by taking a simple ratio of cutting time/tmax to estimate beta. There is an electronic gain inside the CoAguLite sensor that adjusts the LED light output to match the electronics. It only has to be adjusted to keep the output within the sensor voltage range.

The major advantages for the CoAguLite technology are as follows:

It can predict cutting time over a broad range of conditions normally encountered in cheese making

It is easily calibrated by the plant cheese maker

The electronic calibration is simple and flexible.

The CoAguLite sensor has underwent 5 design revisions since 1990 with the CoAguLite Model 5 being the current version. A multitude of adjustments have resulted in a robust sensor design that is durable and gives an impressive noise free signal which makes the determination of subtle differences in milk reactivity visible. A proven sensor robustness and simplicity are an advantage of the CoAguLite technology.

Conclusions

The major advantages for the CoAguLite technology are as follows:

The time-base parameter, tmax, measured using light backscatter is a precise measurement of the enzymatic reaction rate in milk.

The cutting time prediction equation using tmax with protein correction is broadly applicable to a range of conditions normally encountered in cheese making.

The proprietary cutting time prediction model (experimentally verified) uses time-based parameter and is not subject to the problems associated with composition and processing conditions associated with using response-based parameters.

The cutting time prediction equation has only one parameter, Beta, that must be calibrated and it is easily calibrated by the cheese maker.

The CoAguLite optical sensor is a simple, efficient and robust sensor with a proven track record.

References

Payne, F.A., Hicks, C.L., and Shen, Pao-Sheng. 1993. Predicting optimal cutting time of coagulating milk using diffuse reflectance. J. Dairy Science, 76:48-61.

Payne, F.A. and Castillo, M. 2007. Light backscatter sensor applications in milk coagulation. Encyclopedia of Agriculture, Food, and Biological Engineering, 1:1, 1-5.

Saputra, D. 1992. Analysis of enzymatic hydrolysis of milk using diffuse reflectance of near infrared radiation. PhD diss. Lexington, KY.: University of Kentucky, Department of Biosystems and Agricultural Engineering.

Tabayehnejad, N., Castillo M., and Payne F. A. 2009. Comparison of measurement repeatability of the Berridge clotting time method with an optical method for total milk-clotting activity determination. In preparation for submission. Department of Biosystems and Agricultural Engineering, University of Kentucky, Lexington, KY 40546